Residual gas analysis analyzes low levels of residual gas that remain in a vacuum chamber following the pump down. Such gases may include residues from ambient air such as oxygen, nitrogen, and water, along with process residues that may include reactants such as silane, organometallics, halides, etc., and reaction products such as ammonia, hydrogen, moisture, etc.. Remaining gas System leaks and hydrocarbons that backstream into the process chamber from the pumping system can also cause pollutants to accumulate in vacuum chambers.

Product

RGA Series

- Model: RGA Series

- Manufacturer: Hiden Analytical

- Residual gas analysis

- Leak detection

- Desorption

- Outgassing studies

- Bakeout cycles

- Pump Performance

- Process gas contaminants

- Thin film optical coating

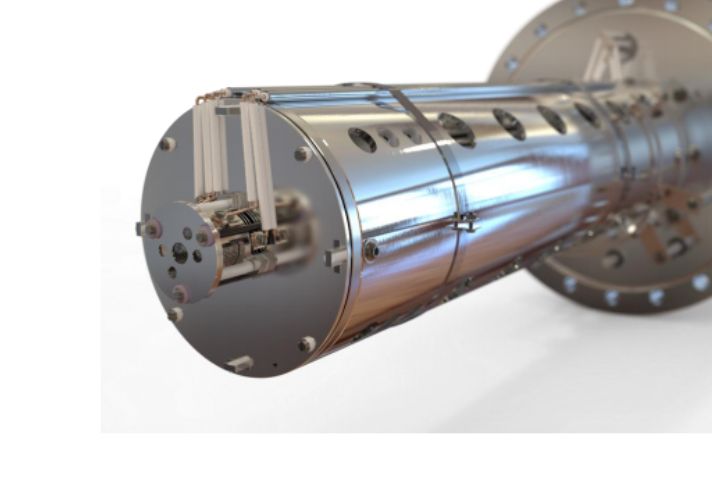

HALO 201 MBE

- Model: HALO 201 MBE

- Manufacturer: Hiden Analytical

- Semiconductor production

- Fuel cells

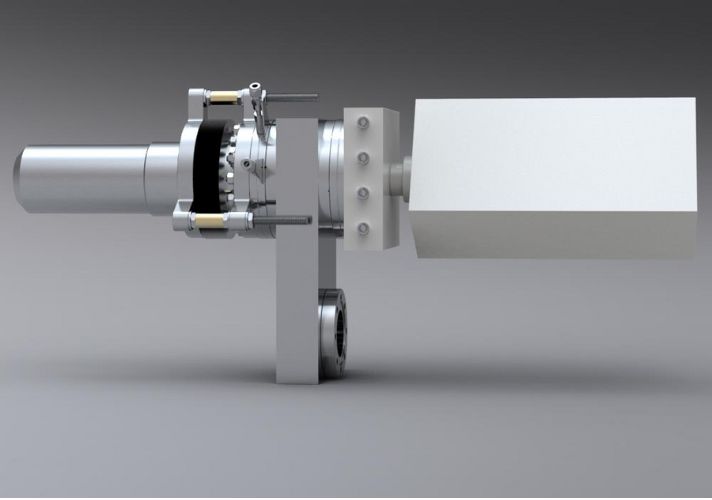

XBS

- Model: XBS

- Manufacturer: Hiden Analytical

- MBE monitoring and control

- Molecular beam studies

- Multiple beam source analysis

- High performance RGA

- Desorption

- Outgassing studies

- Bakeout cycles

- Process gas contaminents

DLS-20

- Model: DLS-20

- Manufacturer: Hiden Analytical

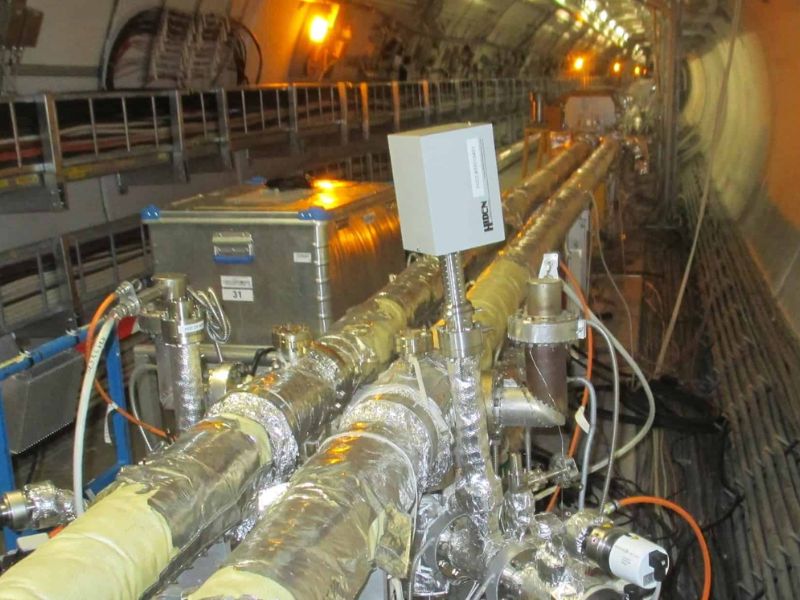

- Fusion research

- Isotope studies

- Synchrotron studies

- Nanotechnology

- Residual gas analysis

3F PIC / 1000 Series PIC

- UHV TPD

- Surface science

- Single crystal studies

- Molecular beam studies

- Flash desorption analysis

- High performance RGA

- Desorption studies

- Bakeout cycles

- Process contaminants

IDP / IDP 1000 Series

- Model: IDP / IDP 1000 Series

- Manufacturer: Hiden Analytical

- Surface science

- Catalysis

Overview

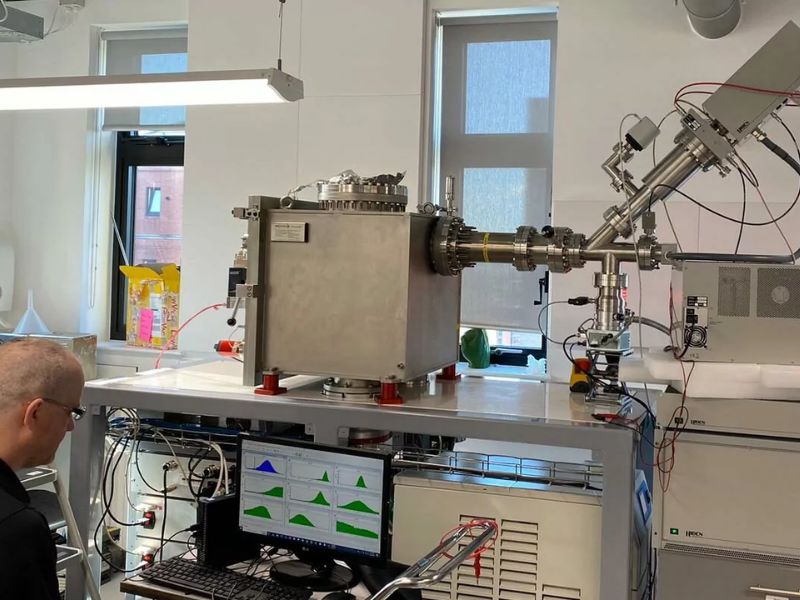

The Reecotech company is the sole distributor of Hiden Analytical’s residual gas analysis (RGA) system in Vietnam. The RGA system is a quadrupole mass spectrometer that is designed to analyze gas types using data collected in real time to give users instantly updated data on the status and partial pressure prediction of residual gas in a vacuum. The information is utilized for vacuum system pollution monitoring, process control, and environmental analysis.

Residual gas analysis mass spectrometry systems can monitor vacuum quality by identifying and quantifying contaminants in a vacuum environment. The RGA is a very sensitive tool for finding gas leaks.

The RGA is usually attached directly to the vacuum chamber. The system performs a variety of functions that are difficult to achieve with other analytical methods including analysis of reactions occurring in different gas phases, and monitoring of changes occurring in any gaseous environment. , vacuum leak detection, and mass flow controller testing.

Principle of operation:

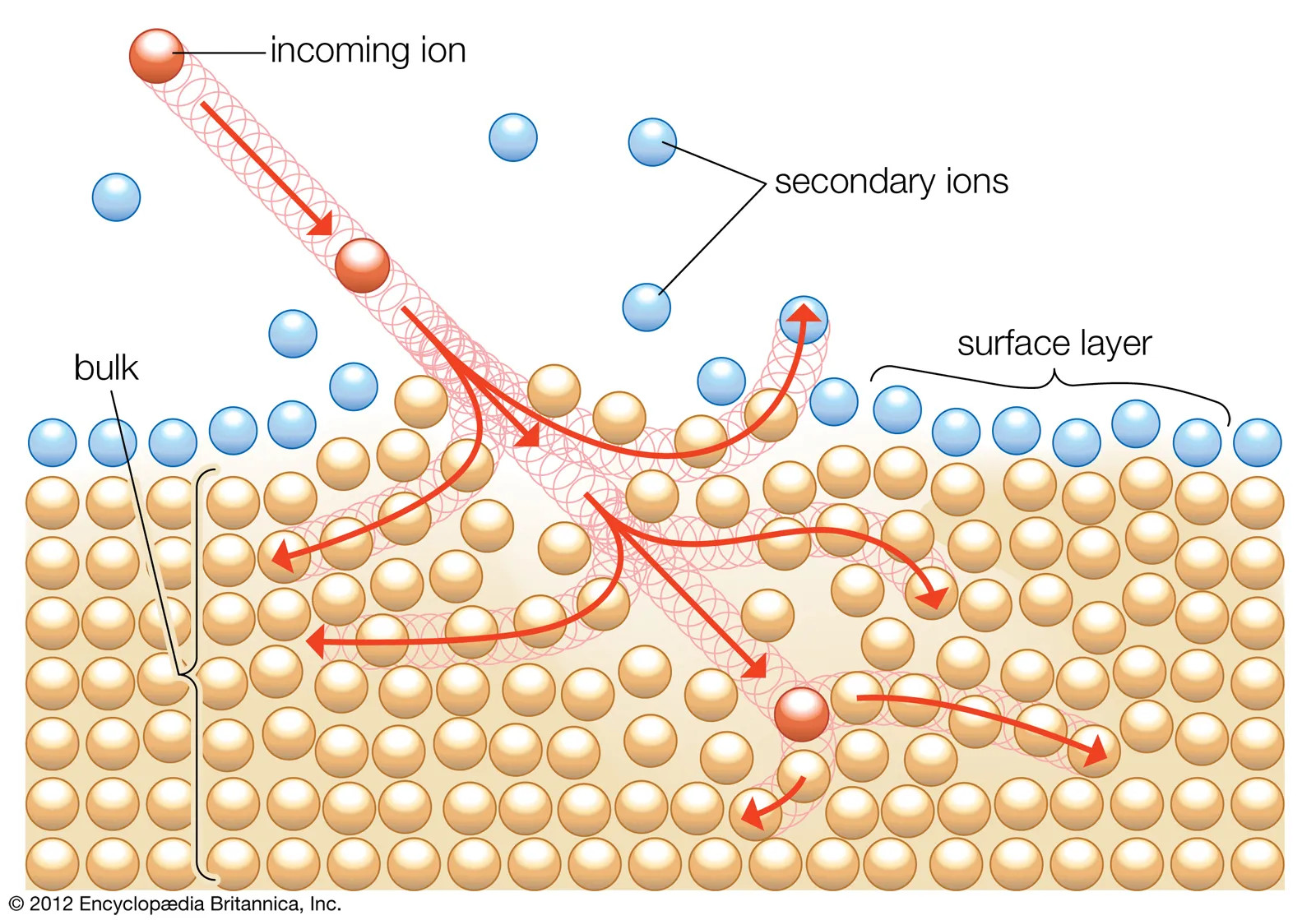

The RGA effectively determines the chemical components of the gas within a vacuum, by ionizing the various gases present to create ions before determining their mass-to-charge ratio.

Aplication

Hiden Analytical’s residual gas quadrupole mass spectrometry system is equipped with multi-level and intuitive software, making it simple to operate for new users, while also incorporating many useful and advanced features. for experts in vacuum research

-

- Residual gas analysis: Residual gas analysis over a wide dynamic range, fast analysis speed and instant data updates provide vacuum chamber leak detection, vacuum quality measurement and monitoring, virtual leak detection, outgassing studies, and bakeout cycle/vacuum pump down monitoring.

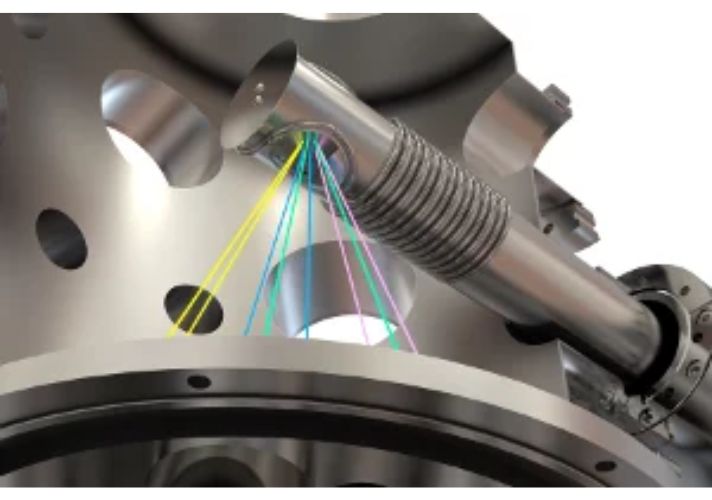

- Systems for Quality Control and Characterisation of MBE Processes: Molecular beam epitaxiality can only be performed under ultra-high vacuum, thin film quality and film forming speed are highly dependent on the purity of the vacuum medium. The HALO 201 MBE residual gas analysis system is designed to analyze vacuum contamination levels and control the ionization zone of the probe to prevent accidental surface deposition. Combined with the Hiden XBS sedimentation rate monitor to analyze the fragment beam and provide signals to control the atomic sedimentation speed.

- Molecular Beam Studies: Hiden’s 3F Series 1000 RGA mass spectrometers feature an ion pulse counter detector and built-in signal port for efficient molecular beam analysis, and a cross-molecular beam analyzer for analysis of fractions. The highly sensitive element prevents contamination of the ionizer and quadrupole from condensed gas residues in the beam.

- Vacuum Process Gas Analysers for CVD / MOCVD / ALD: It is a crucial method used in the production of LEDs and LDs. Hiden’s residual gas analyzers research gas reaction kinetics, evaluate gas composition in industrial processes and monitor chemical vapor deposition processes. They also give information on gas reactions while monitoring.

- Residual Gas Analysis for Vacuum Processing: Hiden Analytical’s residual gas analysis system provides rigorous monitoring of the vacuum process, providing precise monitoring of gas composition to improve process productivity and product quality..