The IMP-EPD is a differentially pumped, ruggedised secondary ion mass spectrometer for the analysis of secondary ions from the ion beam etch process. The system includes integrated software with process specific algorithms developed for optimum process control.

The IMP-EPD system is process proven for the production of high specification thin film devices for applications including magnetic thin films, high temperature superconductors and III-V semiconductors.

The HAL IMP EPD system comprises:

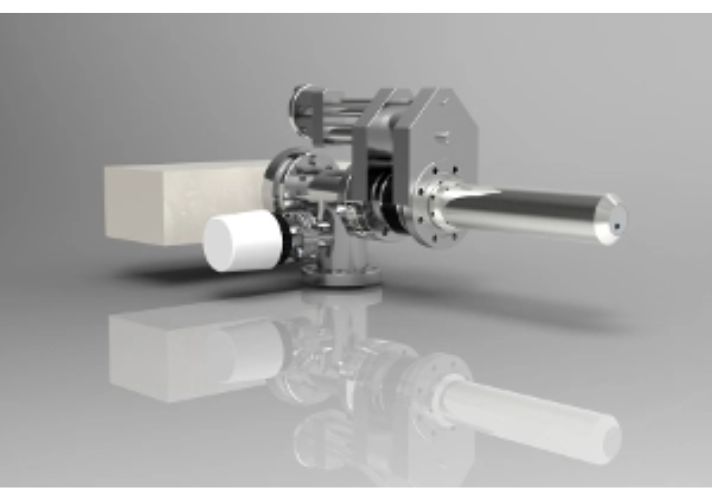

– Type 3F series quadrupole mass spectrometer probe with:

- Triple-stage mass filter for optimum abundance sensitivity and long term stability.

- Integral energy filter for energy resolution of secondary ions.

- Integrated electron bombardment ion source for residual gas analysis.

- Electron multiplier pulse counting detector.

– UHV analyser housing, with sampling aperture and including conflat flange ports for turbomolecular pump and total pressure gauge mounting.

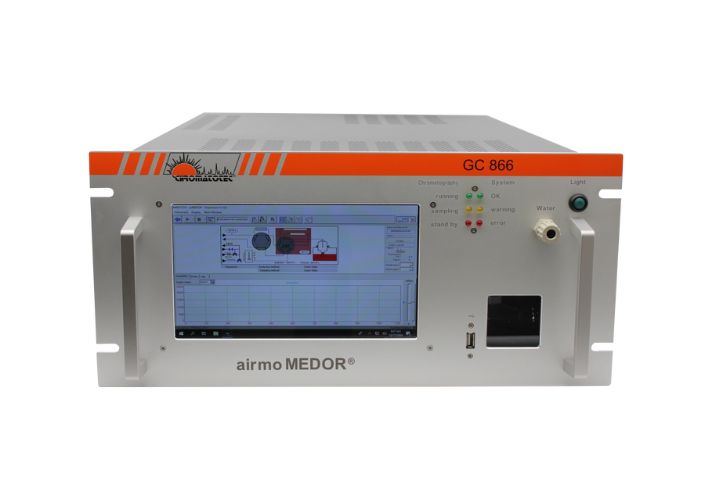

– Control electronics and Windows® MASsoft Professional PC Software with:

- EPD 10-2 RC Interface unit

- RF unit

- Windows® MASsoft PC software enables mass scanning of continuous sequential masses and of selected mass channels with comprehensive data acquisition and presentation routines.

- Automatic endpoint capability of the IMP-EPD system is enabled by the EPD variables option and I/O control that are included in the EPD 10-2 RC Interface unit configuration.

The HAL IMP EPD probes are offered in two alternative forms with standard and extended insertion lengths to assist mounting and positioning in the process chamber:

- Type A, with Bessel-box energy filter, for axial ion acceptance.

- Type B, with parallel-plate energy filter, for ion acceptance at 30° to the probe axis.

Hiden IMP-EPD systems have a working distance from 50mm for small samples up to 150mm for larger samples, production wafers for example. Working distance is the distance from the sample surface to the probe acceptance aperture. Design integration for optimum positioning and mounting of the IMP-EPD probe on the process tool is included.

Review IMP-EPD

There are no reviews yet.