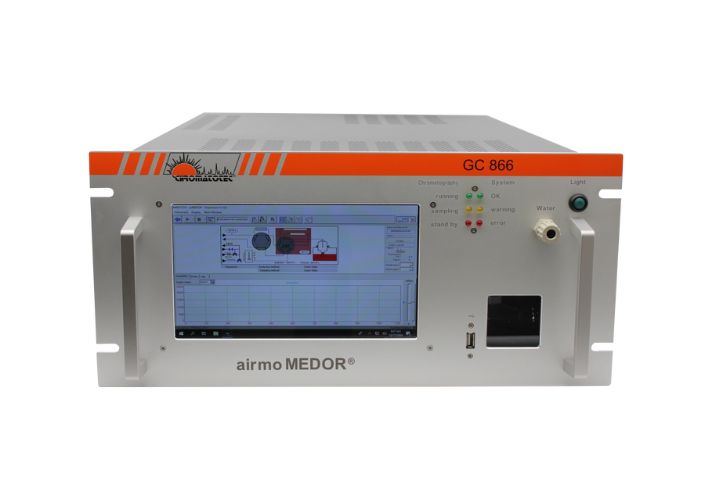

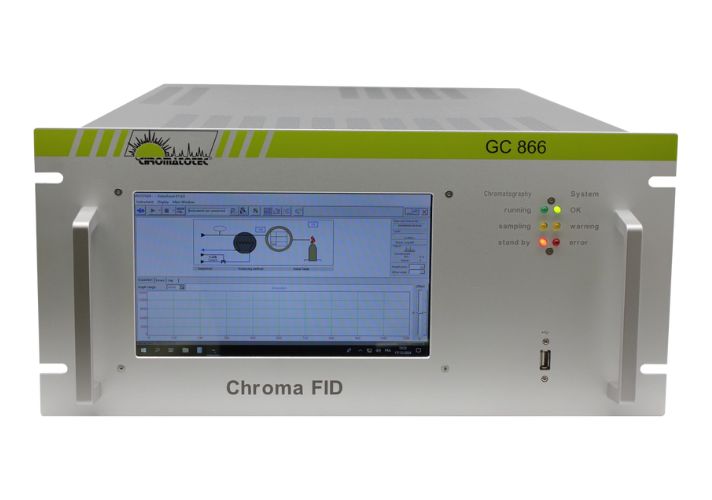

Technical Specifications and Configuration

Sampling and Injection System

- Uses a gate valve combined with a loop for automatic sample collection.

- Injects the sample through the loop directly into the metal capillary chromatography column (internal diameter 0.53 mm).

Chromatography Column and Oven

- Employs a metal capillary chromatography column to ensure stable analysis.

- Features a standard isothermal oven (with an optional programmable temperature gradient) with pressure and carrier gas flow control via valves.

Detection System

- Equipped with a photoionization detector (PID) sensor with a standard 10.6 eV lamp; alternative lamps can be substituted upon request.

- The self-cleaning lamp function maintains high performance and stability during operation.

Communication and Data Output

- Provides a 0–1 V analog output for setting alert thresholds (for low or high concentration warnings).

- Supports two-way RS-232 communication for transmitting data and analysis results to a computer.

Software and Data Storage

- The VISTACHROM Chromatotec® software enables data viewing, storage, processing, and export on a PC.

- Supports calculations of retention time, area, mass, or concentration profiles according to international measurement units.

- Data can be continuously stored for over 10 years with timestamped results.

Operating Principle

-

Sampling and Injection:

The system automatically collects samples via a loop and injects them into the metal capillary chromatography column. -

Gas Chromatographic Analysis:

The device operates in an isothermal mode, separating compounds on the column. -

PID Detection:

Compounds exiting the column are detected by the PID sensor (10.6 eV lamp), with a self-cleaning lamp feature that maintains measurement stability. -

Result Verification:

The system automatically injects a standard to verify and calibrate the measurement results.

Measurement Range

Different configuration versions are available depending on the concentration range:

- ppb Version: For a range of 0–1 ppm.

- ppm Version: For ranges of 0–10, 0–50, or 0–100 ppm.

Analytes

- Benzene (with a TWA of 1 ppm)

- Iso Alcohol Amines

- BTEX, Styrene, Cyclohexane

- 1,3-Butadiene, Iso-Propyl-Benzene (Cumene)

- Epichlorohydrin

Key Advantages

-

Continuous Monitoring:

Online automatic sampling ensures reliable and continuous data acquisition. -

High Analytical Performance:

Demonstrates high specificity, linearity, and sensitivity toward VOC compounds. -

Low Gas Consumption:

Gas usage is minimal and can be further reduced with upgrade options. -

No Need for Compressed Air Cylinders:

Utilizes an internal tube calibration system and gas generator. -

Integrated Automatic Control:

Features adjustable and interactive alarm levels. -

Full Traceability:

Offers result storage and direct chromatogram display on the board. -

Versatile Data Output:

Supports data export via MODBUS protocol and analog outputs (4–20 mA or 0–10 V) with timestamping for each result.

Upgrade Options and Special Versions

-

Wall-Mounted Cabinet:

Includes a touchscreen and supports MODBUS RTU or TCP/IP communication protocols. -

Analog Output Module:

Provides 4 channels of analog output (4–20 mA or 0–10 V). -

24 V Power Supply:

Designed for mobile devices. -

Multi-Channel Sample Flow Selector:

Available in configurations from 2 to 10 channels. -

Nitrogen Gas Generator:

(nitroxychrom, model XXX913CS). -

Calibration System:

Utilizes a benzene diffusion tube. -

Explosion-Proof Version (Exp):

Complies with ATEX, IECEx, Zones 1 and 2, as well as CSA C1D2 standards; equipped with an internal heating/cooling system and insulation for the protective cabinet. -

Liquid Sampling System:

Features a venting function to separate sulfur from the liquid phase (model XXPurge ED Ex). -

GC Oven with Temperature Gradient Capability:

Serves the analysis of multi-component mixtures.

Review BTEX Analyzer Using ChromaPID PID Sensor

There are no reviews yet.