Campbell Scientific’s measurement and control systems provide reliable and versatile data collection at a variety of utilities and energy facilities. Whether your application requires long-term, remote monitoring, or monitoring and control based on complex logic, our systems provide accurate and reliable results. Our data-acquisition systems monitor conditions at power generation plants (hydroelectric, solar, and wind), terminals, substations, oil and gas pumping facilities, commercial and residential consumer sites, and along transmission lines. Key components include data loggers, sensors, and communications devices, which are customized for each application.

Overview

Measurement and Control

Our dataloggers can be used for many different purposes. They can make and record measurements, control electrical devices, or both. Their multifaceted capabilities include functioning as PLCs or RTUs. They have many different channel types, allowing nearly all sensor types to be measured on a single unit. For example, one datalogger can measure voltage, solar radiation, temperature, and gas flow, while controlling a number of peripheral devices. Channel types include analog (single-ended and differential), pulse, switched excitation, and digital. Not only are there multiple types of input channels, but each of these channels can be independently programmed for various sensor types. Most sensors connect directly to the datalogger, eliminating the need for external signal conditioning. Multiplexers and other peripherals can be used with most of our dataloggers to increase the numbers and types of channels.

The ability of our dataloggers to perform advanced control functions is a great advantage. Powerful on-board instruction sets allow unattended measurement and control decisions based on time or conditional events. Using these instruction sets, dataloggers can be programmed to perform multiple control functions based on different scenarios. For example, alarms can be triggered, phone numbers dialed, or equipment shut down if the system detects an equipment failure—all without human intervention.

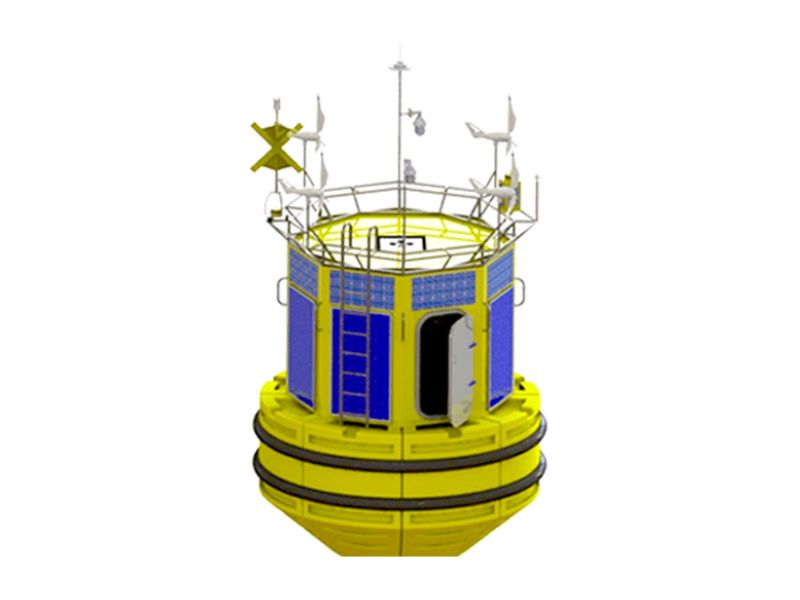

The reliability of our systems ensures the collection of data, even under adverse conditions. Wide operating temperature ranges and weather-proof enclosures allow our systems to operate reliably in harsh environments. Because they have their own power supply (batteries, solar panels), our dataloggers continue to measure and store data and perform control during power outages. Up to 2 million data points can be stored in the datalogger’s non-volatile memory, while storage modules can be used to increase data storage to tens of millions of points. Data is time- and date-stamped to provide key information for identifying and analyzing past events.

Sensors

Almost any sensor can be measured by our dataloggers, allowing the system to be customized for each application. Typical sensors include, but are not limited to: temperature (air, water, equipment, and product), solar radiation, flow (gas and liquid), wind speed and direction, liquid level, electrical current, resistance, power, and voltage.

Communications

The availability of multiple communications options for transmitting data or reporting site conditions also allows our systems to be customized to meet exact needs. Options include: radio, telephone, cellphone, voice-synthesized phone, satellite, and ethernet. As mentioned, systems can be programmed to send alarms or report site conditions by calling out to computers, phones, radios, and pagers.

Monitoring Applications

The open design of our systems allows them to be used in a broad range of applications:

-

- Solar

- Hydroelectric

- Oil and Gas

- Research

- Electric

- Wind