Steam reforming is a process used to produce large quantities of hydrogen from methane, which requires high-purity methane devoid of the odorant compounds present in natural gas. To ensure precise deodorization, it is essential to monitor the emission of sulfur compounds during their separation from natural gas. Reecotech provides a solution for quantifying hydrogen sulfide at two different concentration ranges: high range (low ppm measured directly in the natural gas pipeline) and very low range (low ppb measured after the deodorization process). This dual-range system employs two distinct sampling loops that automatically switch between modes to prevent system saturation or signal issues.

Product

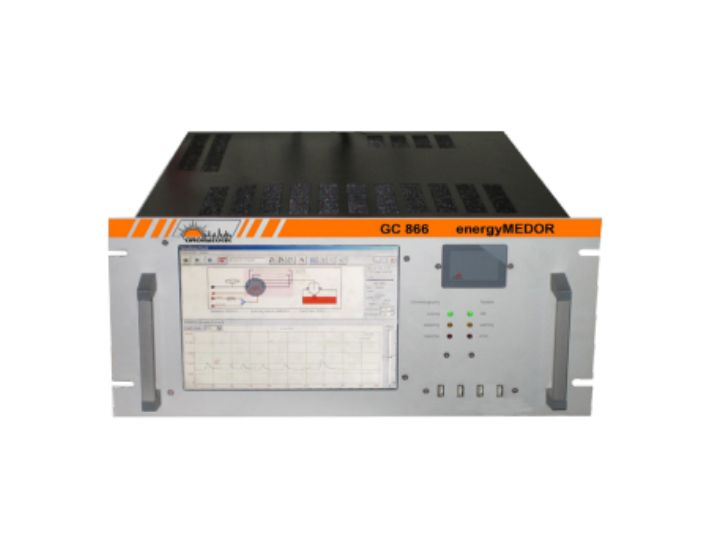

energyMEDOR

The energyMEDOR is an automatic, isothermal gas chromatograph (autoGC-ED) specifically designed for the analysis of sulfur compounds such as H₂S, mercaptans, sulfides, total sulfur, and odor in natural gas and gaseous fuels.

The device provides online and continuous monitoring capabilities, available in two main versions:

- energyMEDOR ppm: Measures sulfur compounds at ppm levels.

- energyMEDOR ppb: Measures sulfur compounds at ppb levels.

Applications

- Detection of impurities in natural gas, LPG, propane, and butane.

- Odor removal control at ppb levels.

- Catalyst protection in chemical processes.

- Odorization control in natural gas or LPG at ppm levels.

Target Compounds

- Standard compounds: THT, H₂S, DMS, and mercaptans (MM, EM, IPM, TBM, NPM, MES, 2BM).

- Optional compounds: IBM and NBM.

Overview

The steam reforming process is a highly efficient technology for hydrogen production from methane. In this application, acquiring high-purity methane and removing odorant compounds from natural gas are crucial for ensuring the quality of the final product. To accurately assess the effectiveness of the deodorization process, it is necessary to monitor the concentrations of the sulfur compounds removed during the gas treatment process.

Chromatotec’s solution enables the quantification of hydrogen sulfide (H₂S) across two concentration ranges:

- High Range: Direct measurement of H₂S concentration in the natural gas pipeline at low ppm levels.

- Very Low Range: Measurement of H₂S concentration after the deodorization process at low ppb levels.

The system is designed with two sampling loops of different volumes, allowing the analytical device to automatically switch between sampling modes. This mechanism prevents signal saturation while maintaining high accuracy during monitoring, thereby enhancing the effectiveness of natural gas quality control and optimizing the hydrogen production process.