In LPG odorization for leak detection, sulfur-containing odorants such as mercaptans and organic sulfides are employed. Gas chromatography is a critical method for the quantitative analysis of these odorants, ensuring that the odorization process achieves optimal effectiveness. Direct analysis from the liquid phase is essential due to potential vapor phase non-uniformity, and the energyMEDOR® auto-GC analyzer equipped with an LPG sampling valve effectively addresses this issue.

Product

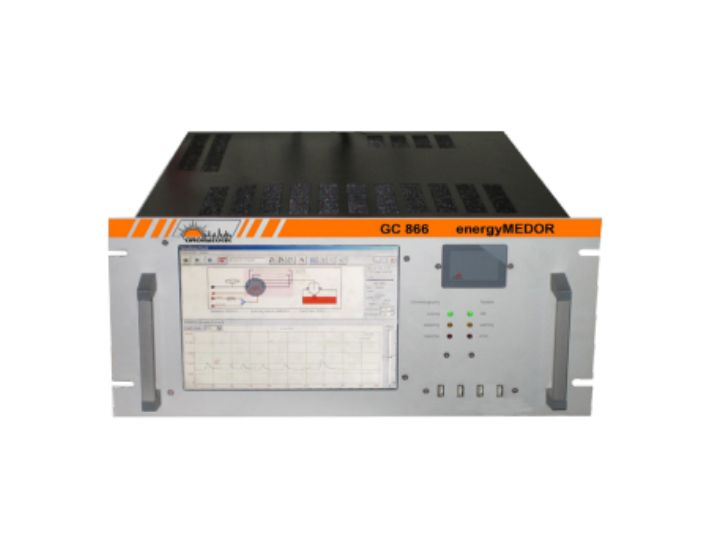

energyMEDOR

The energyMEDOR is an automatic, isothermal gas chromatograph (autoGC-ED) specifically designed for the analysis of sulfur compounds such as H₂S, mercaptans, sulfides, total sulfur, and odor in natural gas and gaseous fuels.

The device provides online and continuous monitoring capabilities, available in two main versions:

- energyMEDOR ppm: Measures sulfur compounds at ppm levels.

- energyMEDOR ppb: Measures sulfur compounds at ppb levels.

Applications

- Detection of impurities in natural gas, LPG, propane, and butane.

- Odor removal control at ppb levels.

- Catalyst protection in chemical processes.

- Odorization control in natural gas or LPG at ppm levels.

Target Compounds

- Standard compounds: THT, H₂S, DMS, and mercaptans (MM, EM, IPM, TBM, NPM, MES, 2BM).

- Optional compounds: IBM and NBM.

Overview

In the context of an industry that increasingly emphasizes safety, odorizing Liquid Petroleum Gas (LPG) to provide leak warning is a mandatory standard. The odorization process is primarily based on sulfur compounds such as mercaptans (including TBM – Tert-Butyl Mercaptan and EM – Ethyl Mercaptan), dimethyl sulfide (DMS), and tetrahydrothiophene (THT) to ensure immediate leak detection. However, the quantitative analysis of these compounds is challenging due to the non-uniformity of the vapor phase during sampling, as differences in boiling points among the components can significantly affect measurement accuracy.

Problem Statement

According to current safety standards, LPG samples taken from the vapor phase tend to be non-uniform. Due to the differences in boiling points among sulfur compounds, these components may distribute unevenly, leading to significant errors in analysis and affecting the assessment of odorization effectiveness.

Traditional sampling and analytical methods often require multiple manual steps—from sample collection to processing—thereby increasing the risk of errors and safety hazards in explosive atmospheres. Moreover, the use of carrier gases or complex pre-treatment equipment further elevates operating costs and prolongs analysis time.

Traditional Manual Method

In conventional analytical procedures, LPG samples are typically collected manually from the vapor phase of the odorant. These samples are then introduced into a gas chromatography system to separate and quantify the sulfur compounds. Although this method has been widely applied, it has several limitations:

- Sample Non-Uniformity: When sampling from the vapor phase, differences in boiling points among the compounds can lead to uneven distribution of sulfur components, resulting in significant quantification errors.

- Multi-Step Manual Process: Manual sample collection and processing can increase measurement errors and the risk of explosion due to handling flammable gases.

- Complex Auxiliary Equipment: The need for carrier gases and pre-treatment devices not only increases operational costs but also extends the analysis time.

Reecotech’s Online Gas Chromatography Solution with an LPG Sampling Valve

To overcome these limitations, Reecotech proposes an advanced solution that integrates a dedicated LPG sampling valve with the energyMEDOR® auto-GC analyzer from Chromatotec. This solution optimizes the LPG analysis process by eliminating the inaccuracies inherent in traditional methods through the following operational principles:

- Direct Liquid-Phase Sampling: Liquid LPG is directly sampled using a dedicated valve, ensuring that the sample is representative and eliminating errors caused by phase separation during vapor phase sampling.

- Controlled Phase Conversion: The liquid LPG sample is subsequently vaporized in a controlled depressurization evaporator, ensuring that all sulfur compounds—including H₂S, mercaptan, DMS, and THT—are completely transferred to the gas phase without loss or thermal degradation.

- Gas Chromatographic Separation and Analysis: The resulting gas sample is then injected into the high-performance GC column of the energyMEDOR® analyzer. Here, the sulfur compounds are separated based on differences in retention time and affinity with the stationary phase, allowing for precise quantification at ppb to ppm levels.

- Specialized Detection and Automatic Calibration: The system integrates a specialized electrochemical detector for sulfur compounds, along with an internal diffusion calibrator, ensuring long-term accuracy and stability of the analytical results.

- Real-Time Data Transmission: Finally, the analytical results are processed and transmitted in real time via the Modbus protocol, supporting continuous monitoring and stringent quality control of LPG, thereby enhancing operational safety.

Advantages

- Fast Analysis: Each chromatographic cycle takes approximately 10 minutes with a sample volume of only 1 μL, enabling precise quantification of sulfur compounds at very low concentrations (ppb/ppm).

- Direct Liquid Sampling and Automation: Direct sampling from the liquid phase combined with automation minimizes manual handling errors and increases quantitative accuracy.

- Simplified Operation: The system requires only N₂ or air as the carrier gas, thereby simplifying operation and reducing consumable costs.

- Safety and Compliance: The system meets ASTM D7493-08 standards and is certified for explosion safety in hazardous environments in accordance with ATEX, IECEx Zone 1, and CSA C1D2.

- Integrated Software: The Vistachrom control software supports real-time data connectivity via the Modbus protocol, facilitating effective monitoring and quality management of LPG.

Reecotech’s online gas chromatography solution not only overcomes the limitations of traditional analytical methods but also delivers high analytical performance, superior accuracy, and long-term stability. Direct liquid-phase sampling combined with a highly automated process enhances the control and monitoring of LPG quality, thereby contributing to elevated safety standards and ensuring product quality in the LPG industry.