Chromatotec®’s H₂S MEDOR analyzer measures the real-time H₂S concentration in the recycled hydrogen gas stream, which contains up to 60% H₂, along with propane and propylene, within an H₂S concentration range of 0–1 ppm

Product

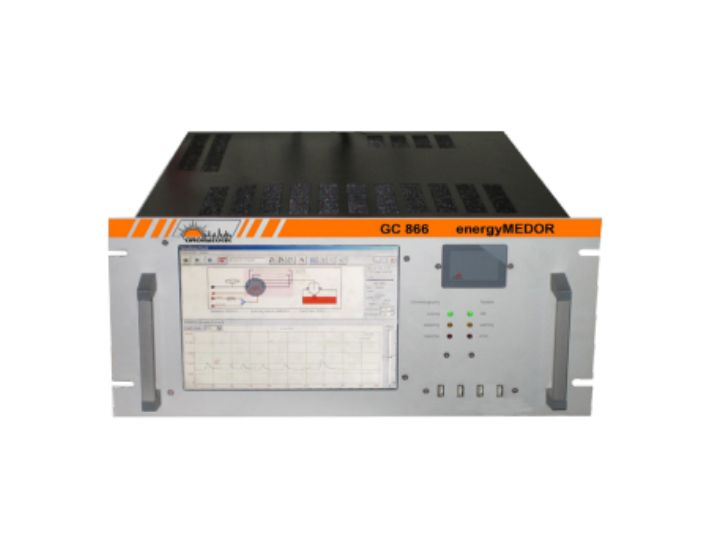

energyMEDOR

The energyMEDOR is an automatic, isothermal gas chromatograph (autoGC-ED) specifically designed for the analysis of sulfur compounds such as H₂S, mercaptans, sulfides, total sulfur, and odor in natural gas and gaseous fuels.

The device provides online and continuous monitoring capabilities, available in two main versions:

- energyMEDOR ppm: Measures sulfur compounds at ppm levels.

- energyMEDOR ppb: Measures sulfur compounds at ppb levels.

Applications

- Detection of impurities in natural gas, LPG, propane, and butane.

- Odor removal control at ppb levels.

- Catalyst protection in chemical processes.

- Odorization control in natural gas or LPG at ppm levels.

Target Compounds

- Standard compounds: THT, H₂S, DMS, and mercaptans (MM, EM, IPM, TBM, NPM, MES, 2BM).

- Optional compounds: IBM and NBM.

Overview

In modern petrochemical complexes, propane dehydrogenation (PDH) technology plays a crucial role in producing polymer-grade propylene for the chemical and plastics industries. In the PDH reactor, propane is introduced into a metal catalyst system where dehydrogenation reactions occur, producing a product mixture of propylene and hydrogen gas.

To optimize energy efficiency and reduce operating costs, the hydrogen gas recovered from the PDH reactor is continuously circulated and reused within the system. However, if the incoming propane feed is not thoroughly desulfurized, hydrogen sulfide (H₂S) may form and accumulate in the recycled hydrogen gas.

Even at trace levels, H₂S in the recycled hydrogen gas can pose serious risks, including:

- Catalyst poisoning: Reduced catalytic activity, shortened catalyst lifespan, and impaired reaction performance.

- Equipment and pipeline corrosion: Particularly in the hydrogen-rich, high-temperature environment of the PDH unit.

- Increased maintenance and repair costs: Along with a heightened risk of unplanned plant shutdowns, affecting both safety and production efficiency.

Requirement for H₂S Control in Recycled Hydrogen Gas

In view of these risks, implementing a continuous online monitoring system to measure and monitor H₂S directly in the recycled hydrogen gas line downstream of the PDH reactor is essential. This approach aims to:

- Detect H₂S at trace concentrations early, preventing dangerous accumulation.

- Protect catalysts and equipment from the corrosive effects of H₂S.

- Maintain stable, safe, and continuous operation of the entire PDH process line.

Reecotech proposes the Chromatotec MEDOR® online H₂S analyzer, which employs automated gas chromatography (AutoGC) technology combined with a specialized sulfur-specific electrochemical wet cell detector (ED).

Key Technical Specifications

- Wide Measurement Range: 0–1 ppm H₂S, with a detection limit as low as 1 ppb.

- Sample Gas Composition: A mixture containing up to 60% hydrogen along with propane and propylene.

- High Selectivity: Reacts only with sulfur compounds, unaffected by hydrogen or light hydrocarbons.

- Linearity: R² > 0.995 across the entire measurement range, ensuring stable accuracy.

- Stable Performance in Humid Environments: The MEDOR® detector is not influenced by moisture present in the sample gas.

Technical and Operational Characteristics

- Continuous 24/7 Operation: Provides real-time analytical data to the plant’s DCS or SCADA system.

- Integrated Internal Nitrogen (N₂) Generator: Eliminates the need for external hydrogen or calibration gases, thereby optimizing operating costs.

- Automatic Calibration: Ensures long-term accuracy and minimizes the need for manual maintenance.

- Robust Design for Harsh Industrial Environments: Meets international safety standards for hazardous areas, including:

- ATEX (Europe)

- IECEx (International)

- CSA and CSA International (North America)

Benefits of Implementing the Solution

Integrating the MEDOR® H₂S analyzer into the PDH process line offers significant technical and operational advantages:

- Catalyst Protection: Prevents catalyst poisoning, extends catalyst lifespan, and maintains stable reaction performance.

- Equipment Protection: Minimizes corrosion, reduces maintenance and repair costs, and optimizes system longevity.

- Process Stability: Early detection of H₂S levels exceeding permissible limits allows for timely operational adjustments.

- Optimized Operating Costs: Reduces the consumption of desulfurization chemicals and enhances the efficiency of hydrogen gas recovery.

- Compliance with International Safety Standards: Adheres to strict regulations for controlling toxic gases in petrochemical production environments.

The installation of the MEDOR® online H₂S analyzer for recycled hydrogen gas in the PDH process line is not only an advanced technical solution but also an essential requirement to ensure safety, optimize operations, and protect assets in modern petrochemical complexes.