Reecotech supplies the airmoQuality system from Chromatotec, which comprises a 19-inch rack cabinet equipped with an industrial computer, a calibration unit, and one to three gas analyzers. This system is designed to quantify various components – including pure gases, sulfur compounds, carbon monoxide (CO), carbon dioxide (CO₂), volatile organic compounds (VOCs), methane (CH₄), ammonia (NH₃), amines, and other permanent gases – across a range of concentration levels, thereby ensuring optimal gas quality for industrial applications.

Product

ChromaTHC Total Hydrocarbon Analysis System

-

- Clean Air Room

- Ambient Air Monitoring

- Waste Water Treatment Plant

- Impurities in pure gas processing

- Emissions monitoring

- Filter integrity monitoring

- VOC/UHC monitoring (Industrial Hygiene) in option

- Fence Line monitoring

- Odor control monitoring

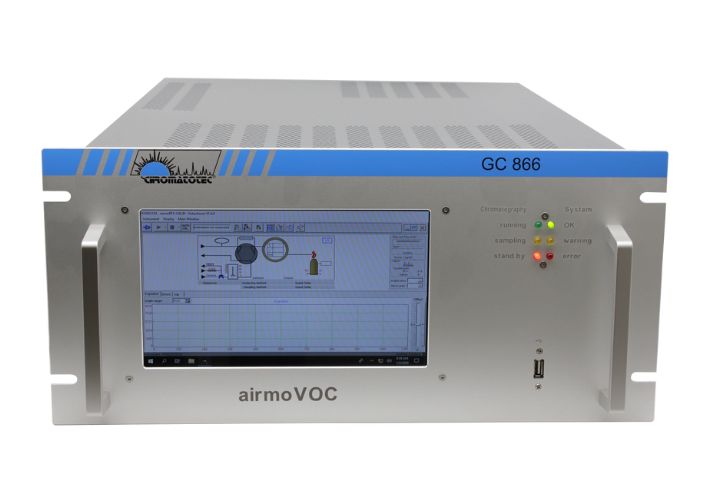

AirmoVOC C2-C6 Light Volatile Hydrocarbon Analyzer

This device is capable of detecting compounds such as ethane, 1,3-butadiene, benzene, and other C6 compounds, enabling air pollution control, environmental monitoring, and air quality assessment in both indoor environments and industrial processes.

Applications

- Environmental pollution control: Monitoring air quality in urban and suburban areas.

- Indoor air analysis: Evaluating air pollution levels in workplaces or living environments.

- Industrial and factory emission monitoring: Assessing exhaust gases from factories, industrial zones, and environmental protection perimeters.

- Toxic gas emission assessment: Detecting hazardous compounds such as benzene and 1,3-butadiene to ensure health and safety.

- VOC screening in the food and beverage industry: Ensuring CO₂ gas quality used in food and beverage production.

Light Hydrocarbon and BTEX Analysis System – airmoVOC 624

The airmoVOC 624 analysis system is designed to measure volatile organic compounds (VOCs), including BTEX (Benzene, Toluene, Ethylbenzene, and Xylene). The device is capable of analyzing up to 49 compounds using the TO14 or PAMS methods.

Applications

Environmental Monitoring

- Air pollution control in urban and industrial areas.

- Indoor air quality assessment.

- Monitoring BTEX, PAMS, and CE compounds.

Industrial Process Monitoring

- Measurement of emissions from factories and production lines.

- Occupational safety and industrial hygiene monitoring.

- Fence line monitoring to control emissions at factory boundaries.

Wastewater and Ambient Air Monitoring

- Emission control in wastewater treatment plants using the Purge and Trap method (502-2 or 524).

- Ambient air monitoring following PAMS and TO14 standards.

AirmoVOC BTX – Automatic GC/FID BTEX Monitoring System

Applications

Environmental Monitoring

- Monitoring urban and rural pollution.

- Industrial pollution tracking.

Industrial Applications

- Occupational health and safety monitoring.

- Process quality control.

Other Applications

- VOC analysis in wastewater (headspace, ppt).

- Drinking water testing.

- CO₂ purity control in the beverage industry.

Heavy volatile hydrocarbon analysis system AirmoVOC C6-C12

The AirmoVOC C6-C12 is an advanced analyzer designed for the measurement of volatile hydrocarbon compounds, including BTEX (Benzene, Toluene, Ethylbenzene, and Xylene) as well as halogenated compounds (TO14). This device can analyze up to 53 compounds within the C6-C12 range, making it ideal for environmental monitoring, industrial emissions surveillance, and air quality control.

Applications

Environmental Monitoring:

- Air pollution control in urban and non-urban areas.

- Indoor air quality measurement.

- BTEX, PAMS, and Volatile Organic Compounds (VOC) analysis.

Industrial Emission Surveillance:

- Pollution control from factories and industrial zones.

- Fence line monitoring to track emissions at facility boundaries.

Other Applications:

- Ambient air monitoring around wastewater treatment plants.

- VOC analysis in water using the Purge and Trap method (502-2 or 524).

- Air quality surveillance following PAMS and TO14 methods.

ChromaTCD

The ChromaTCD system is an automated gas chromatography (autoGC) device with an isothermal design, specifically developed for analyzing permanent gases and light hydrocarbons in ambient air, industrial environments, or pure gases (N₂/CO₂/O₂).

Applications

- Quality control of ultra-high purity (UHP) gases in production and research.

- Monitoring air quality in ambient or industrial environments.

- Gas emissions analysis and odor impact management.

- Fermentation monitoring and industrial production processes.

- Detection of impurities in pure gas processing.

- Integrity testing of filters in industrial applications.

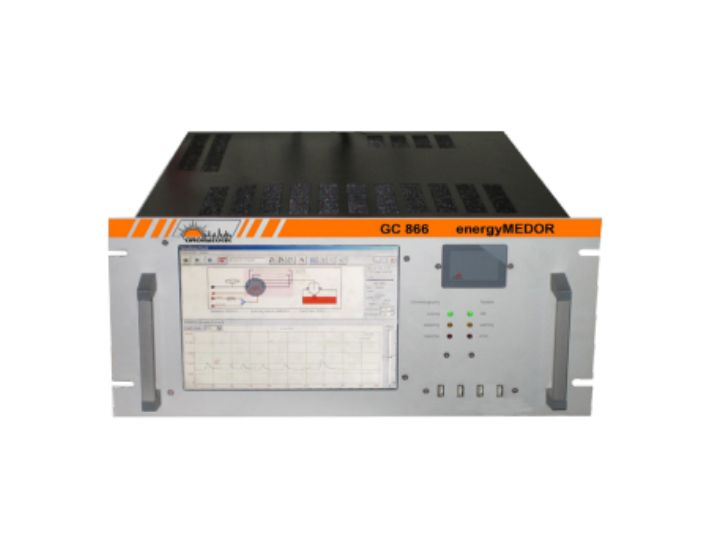

energyMEDOR

The energyMEDOR is an automatic, isothermal gas chromatograph (autoGC-ED) specifically designed for the analysis of sulfur compounds such as H₂S, mercaptans, sulfides, total sulfur, and odor in natural gas and gaseous fuels.

The device provides online and continuous monitoring capabilities, available in two main versions:

- energyMEDOR ppm: Measures sulfur compounds at ppm levels.

- energyMEDOR ppb: Measures sulfur compounds at ppb levels.

Applications

- Detection of impurities in natural gas, LPG, propane, and butane.

- Odor removal control at ppb levels.

- Catalyst protection in chemical processes.

- Odorization control in natural gas or LPG at ppm levels.

Target Compounds

- Standard compounds: THT, H₂S, DMS, and mercaptans (MM, EM, IPM, TBM, NPM, MES, 2BM).

- Optional compounds: IBM and NBM.

Overview

In the chemical, petroleum, and high-tech industries, ensuring the purity of Ultra High Purity (U.H.P.) gases is critical for maintaining operational performance, prolonging equipment lifespan, and guaranteeing product quality. Even trace amounts of impurities can significantly affect production processes and system operations; therefore, monitoring and controlling impurities in U.H.P. gases prior to market delivery is essential.

Reecotech introduces the airmoQuality solution—a comprehensive, fully automated pure gas analysis system specifically designed for detecting and controlling impurities in U.H.P. gases—with the following key features:

- High Sensitivity: Capable of detecting impurity concentrations from parts per billion (ppb) and parts per million (ppm) up to percentages (%).

- Strict Compliance: Meets the rigorous standards required by the chemical, petroleum, and high-tech manufacturing industries.

The system is designed as a flexible, modular solution that can be easily customized and scaled according to specific requirements, and it includes the following main components:

- 19-inch Rack Cabinet: Integrates all analytical and control equipment within a compact enclosure.

- Industrial Computer: Processes and stores data with high accuracy and speed.

- Calibration Unit: Ensures continuous maintenance of measurement accuracy throughout the operational cycle.

- Gas Analyzers: Configurable with one to three devices, utilizing advanced technology to measure various impurities as required.

The airmoQuality system can simultaneously monitor several critical impurities in U.H.P. gases, including:

| Analyte | Technology/Equipment Used | Measurement Range | Control Objective |

|---|---|---|---|

| Pure Gas | chromaTCD | ppm or % | Determine the concentration of pure gas and detect major impurities. |

| Sulfur Compounds (H₂S, SO₂, other sulfur compounds) | energyMEDOR or ChromaS | ppb – ppm | Detect sulfur compounds that cause unpleasant odors and equipment corrosion. |

| CO and CO₂ in Pure Gas | chromaCO | ppb | Monitor CO and CO₂ contamination affecting product quality. |

| VOCs (e.g., acetone, formaldehyde) | airmoVOC | ppb | Detect VOCs to control contamination and ensure gas quality. |

| CH₄ and NMTHC (Non-Methane Total Hydrocarbons) | chromaTHC | ppb | Monitor methane and non-methane hydrocarbons that contribute to impurities. |

| NH₃ and Amines | airmoQuality | ppb | Detect ammonia and amines that may adversely affect products and equipment. |

| Permanent Gases (He, Ar, H₂, O₂, N₂, CH₄, etc.) | airmoQuality | ppb | Ensure high purity levels in production processes. |

Benefits of Implementing the airmoQuality System

- Continuous, Automated, and Accurate Monitoring: Ensures that impurities affecting U.H.P. gas quality are constantly tracked.

- Compliance with Stringent Standards: Meets the rigorous requirements of industries that demand high purity.

- Flexible and Scalable Configuration: Easily adaptable and expandable to meet the specific needs of various production lines.

- Optimized Quality Control: Enhances quality control processes to ensure that high-purity gases achieve absolute purity before delivery to customers.

With this solution, businesses can be assured of the stability, safety, and operational efficiency required when using U.H.P. gases in critical industrial applications.