Cleanrooms must be continuously monitored to ensure both worker safety and product quality. CHROMATOTEC’s airmoVOC and airmo C10-C18 analyzers can detect trace levels of volatile organic compounds (VOCs), thereby reducing the need for costly laboratory analyses. Effective VOC monitoring is critical to maintaining uninterrupted production processes, minimizing financial losses, and upholding manufacturing standards.

Product

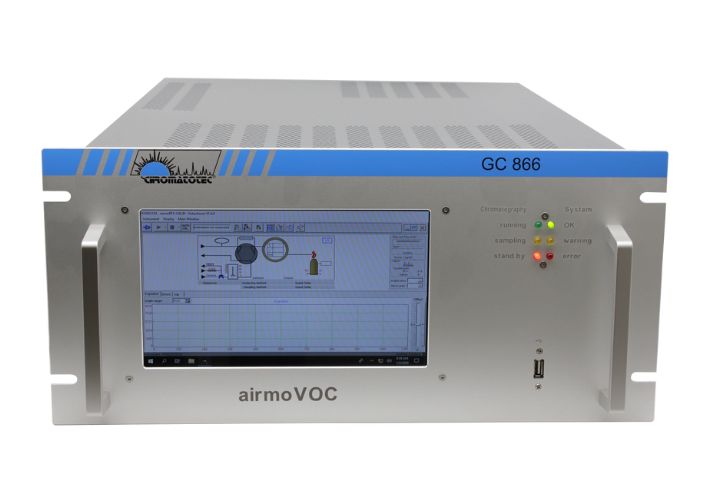

AirmoVOC C2-C6 Light Volatile Hydrocarbon Analyzer

This device is capable of detecting compounds such as ethane, 1,3-butadiene, benzene, and other C6 compounds, enabling air pollution control, environmental monitoring, and air quality assessment in both indoor environments and industrial processes.

Applications

- Environmental pollution control: Monitoring air quality in urban and suburban areas.

- Indoor air analysis: Evaluating air pollution levels in workplaces or living environments.

- Industrial and factory emission monitoring: Assessing exhaust gases from factories, industrial zones, and environmental protection perimeters.

- Toxic gas emission assessment: Detecting hazardous compounds such as benzene and 1,3-butadiene to ensure health and safety.

- VOC screening in the food and beverage industry: Ensuring CO₂ gas quality used in food and beverage production.

Light Hydrocarbon and BTEX Analysis System – airmoVOC 624

The airmoVOC 624 analysis system is designed to measure volatile organic compounds (VOCs), including BTEX (Benzene, Toluene, Ethylbenzene, and Xylene). The device is capable of analyzing up to 49 compounds using the TO14 or PAMS methods.

Applications

Environmental Monitoring

- Air pollution control in urban and industrial areas.

- Indoor air quality assessment.

- Monitoring BTEX, PAMS, and CE compounds.

Industrial Process Monitoring

- Measurement of emissions from factories and production lines.

- Occupational safety and industrial hygiene monitoring.

- Fence line monitoring to control emissions at factory boundaries.

Wastewater and Ambient Air Monitoring

- Emission control in wastewater treatment plants using the Purge and Trap method (502-2 or 524).

- Ambient air monitoring following PAMS and TO14 standards.

AirmoVOC BTX – Automatic GC/FID BTEX Monitoring System

Applications

Environmental Monitoring

- Monitoring urban and rural pollution.

- Industrial pollution tracking.

Industrial Applications

- Occupational health and safety monitoring.

- Process quality control.

Other Applications

- VOC analysis in wastewater (headspace, ppt).

- Drinking water testing.

- CO₂ purity control in the beverage industry.

Heavy volatile hydrocarbon analysis system AirmoVOC C6-C12

The AirmoVOC C6-C12 is an advanced analyzer designed for the measurement of volatile hydrocarbon compounds, including BTEX (Benzene, Toluene, Ethylbenzene, and Xylene) as well as halogenated compounds (TO14). This device can analyze up to 53 compounds within the C6-C12 range, making it ideal for environmental monitoring, industrial emissions surveillance, and air quality control.

Applications

Environmental Monitoring:

- Air pollution control in urban and non-urban areas.

- Indoor air quality measurement.

- BTEX, PAMS, and Volatile Organic Compounds (VOC) analysis.

Industrial Emission Surveillance:

- Pollution control from factories and industrial zones.

- Fence line monitoring to track emissions at facility boundaries.

Other Applications:

- Ambient air monitoring around wastewater treatment plants.

- VOC analysis in water using the Purge and Trap method (502-2 or 524).

- Air quality surveillance following PAMS and TO14 methods.

Overview

In cleanroom environments, sustaining high air quality is essential for protecting personnel and ensuring product integrity. Cleanrooms are engineered to strictly control particulate levels and airborne contaminants, preventing the ingress, generation, and accumulation of dust. This is particularly vital in high-precision industries such as semiconductor manufacturing and pharmaceuticals. Consequently, continuous monitoring of air quality indices is indispensable to guarantee that the work environment remains compliant and production processes are not adversely affected.

Reecotech offers advanced automated gas chromatography solutions that provide continuous and accurate monitoring of cleanroom air quality, with the following key features:

- Simultaneous Monitoring of Multiple Cleanrooms: Utilizing a 6-stream multiplexer technology along with Vistachrom monitoring software, Reecotech can concurrently monitor the air quality in up to six different cleanrooms. This system enables real-time assessment across various spaces, reducing manual intervention and saving time. It continuously measures VOC concentrations at extremely low levels (from ppb to ppt) from air samples drawn within the cleanroom, ensuring that the environment consistently meets high-quality standards.

- Continuous VOC Monitoring: Reecotech’s automated gas chromatography instruments, such as airmoVOC and airmo C10-C18, are specifically designed to monitor VOC concentrations within cleanrooms. This continuous monitoring allows for the prompt detection of any changes in VOC levels, especially when they exceed safety thresholds. Unlike traditional manual sampling and subsequent laboratory analysis, this automated system not only reduces costs but also enhances accuracy and the timeliness of incident detection.

- Process Gas Monitoring: Beyond cleanroom air monitoring, the system is capable of overseeing process gases used in production to ensure they do not compromise product quality. Reecotech’s gas analyzers monitor these gases continuously, ensuring that production conditions remain stable and meet stringent quality requirements.

By significantly reducing costs compared to manual sampling and laboratory analysis, the automated gas monitoring system enhances both the accuracy and promptness of air quality assessments. Early detection of any anomalies in gas concentrations supports enterprises in taking timely measures to maintain safe and efficient production.