In the food and beverage industry, ensuring the quality and safety of carbon dioxide (CO₂) is critically important due to its use in a wide range of applications. Reecotech offers gas chromatography (GC) analytical systems for monitoring CO₂ quality. These analyzers detect impurities such as sulfur compounds and benzene, ensuring compliance with health and safety regulations and making them ideal for CO₂ quality control.

Product

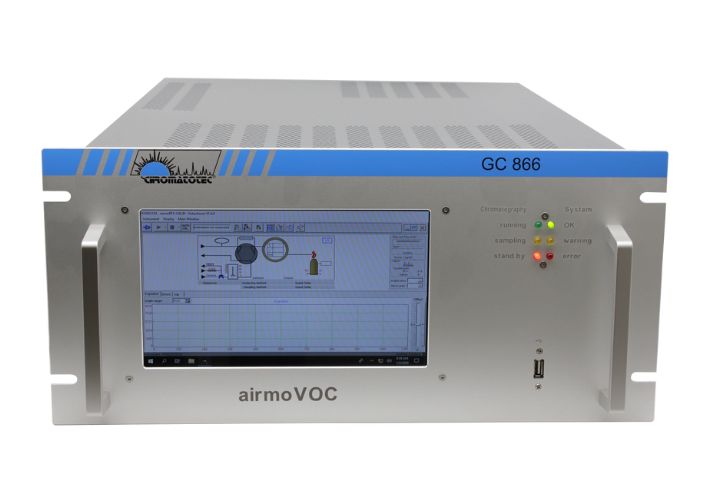

AirmoVOC BTX – Automatic GC/FID BTEX Monitoring System

Applications

Environmental Monitoring

- Monitoring urban and rural pollution.

- Industrial pollution tracking.

Industrial Applications

- Occupational health and safety monitoring.

- Process quality control.

Other Applications

- VOC analysis in wastewater (headspace, ppt).

- Drinking water testing.

- CO₂ purity control in the beverage industry.

Overview

Carbon dioxide (CO₂) is an essential component widely used in the food and beverage industry, especially in the production of carbonated soft drinks, beer, and champagne. However, during the industrial production and purification of CO₂, various unwanted impurities may arise, including:

- Ammonia (NH₃)

- Acetaldehyde

- Benzene and BTEX compounds (Benzene, Toluene, Ethylbenzene, Xylene)

- Total hydrocarbon content

- Sulfur compounds (H₂S, SO₂, COS, Mercaptans, …)

Although these impurities exist only in very small concentrations, they can affect the taste, aroma, and color of the product while posing potential health risks to consumers. Consequently, stringent standards have been implemented to control the quality of CO₂ used in food and beverages, notably the CO₂ Guidelines issued by the International Society of Beverage Technologists (ISBT), which specify limits for each compound.

Ensuring that CO₂ meets the required standards is not only a legal obligation but also serves to:

- Ensure food safety and protect consumer health

- Maintain the flavor and quality of the product

- Enhance brand reputation in both domestic and international markets

- Comply with export standards in demanding markets such as the EU, the United States, and Japan

To support food and beverage companies in effectively controlling CO₂ quality, Reecotech introduces an advanced analytical solution using Chromatotec’s automated gas chromatography (GC) system, which offers high accuracy and stable operation in industrial production environments.

The system comprises two specialized analytical modules:

- chromaS COS: Utilizes a dual flame photometric detector (Dual FPD) to accurately detect sulfur compounds such as H₂S, SO₂, COS, CS₂, Mercaptans, DMS, and DMDS.

- airmoVOC BTEX: Employs a flame ionization detector (FID) to analyze acetaldehyde and aromatic hydrocarbons of the BTEX group.

These two modules are integrated to operate in parallel, enabling multi-component measurements with high sensitivity. They can detect impurities at extremely low concentrations (ppb – ppm) and ensure that CO₂ quality remains consistently stable throughout the production process.

The Chromatotec system is optimally designed to simultaneously analyze the primary groups of impurities in CO₂, including:

- Sulfur compounds that cause unpleasant odors and corrode equipment

- The BTEX group – toxic aromatic hydrocarbons

- Aldehydes (acetaldehyde) that affect beverage flavor

- Total hydrocarbons and VOCs that lead to flavor instability

- Other toxic gases such as COS, SO₂, and sulfur derivatives

The analytical parameters adhere to the ISBT CO₂ Guidelines, ensuring that the product achieves the highest quality and absolute safety.

Key Advantages of the Solution:

- Detects impurities at extremely low concentrations, meeting international safety standards.

- Enables 24/7 automated operation, reducing the need for manual supervision and suiting modern production lines.

- Delivers long-term result stability, reducing maintenance costs and downtime.

- Offers easy installation, simple operation, and low maintenance expenses.

- Continuously records data, provides threshold breach alerts, and supports historical traceability along with quality control report generation.

- Eliminates risks affecting the taste, purity, and safety of beverages.

- Complies with legal standards and export requirements in stringent markets such as the EU, the United States, and Japan.

With Reecotech’s real-time automated gas chromatography solution, companies in the food and beverage industry can have complete confidence in their CO₂ quality while protecting their brand and sustainably expanding their export markets.