ATi’s water quality and toxic gas monitoring system is an automated solution designed to continuously measure and record key water quality and gas indicators for the Food & Beverage industry. This solution enables production facilities to uphold stringent hygiene and safety standards, protect employee health, and optimize processes while minimizing risk. With flexible integration across various production environments—from beverage production and meat processing to bars and restaurants—ATi’s system ensures safety, regulatory compliance, and supports sustainable development in manufacturing.

Product

Q46/85 Peracetic Acid Monitor

- Reliable chemical feed control

- Interference-free measurement

- Multiple flowcell options

- Food & Beverage

- Medical Disinfection

- Egg Washers

- Cooling Water

- Wastewater

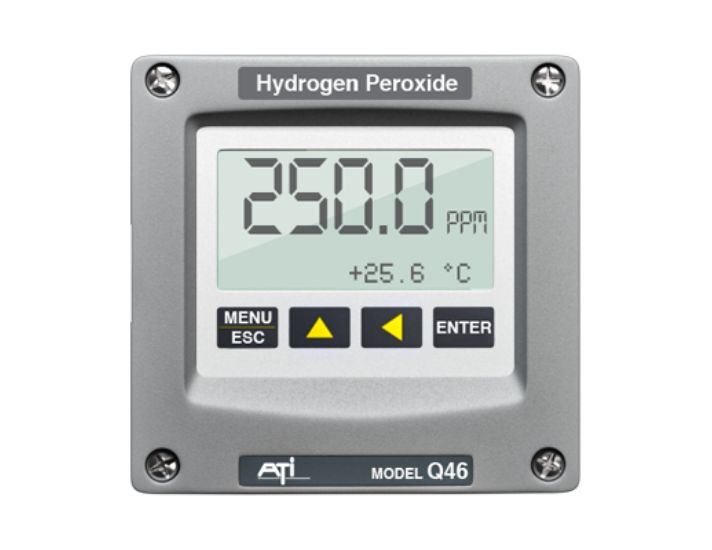

Q46/84 Hydrogen Peroxide Monitor

- Multiple flowcell options

- Monitors pressures up to 50 PSI

- For simple installation, complete flow control assemblies are available

- Cooling Water

- Aquarium

- Food & Beverage

- Potable Water Treatment

- Odour Control.

Q46H/62-63 Residual Chlorine Monitor

- Free or combined chlorine

- Automatic pH compensation

- Reagent free

- Dual Chlorine/pH Monitoring

- Potable water systems

- Water reuse systems

- Cooling towers

- Aquariums

- Wastewater treatment effluents.

Q46H/64 Dissolved Ozone Monitor

- Wide dynamic range for maximum flexibility

- pH input option

- Multiple sensor flowcell options

- Low maintenance membrane sensor

- The Q46H/64 Dissolved Ozone Monitor is available for a wide range of applications including

- Food & Beverage

- Pharmaceutical Manufacturing

- Semi-Conductor Water Treatment

- Cooling Water

- Potable Water Treatment

- Aquarium

Q46P/R pH/ORP Monitor

- Differential or conventional pH sensors available

- Automatic buffer recognition simplifies calibration

- Q-Blast sensor cleaning option available

- Multiple sensor mounting options

- Water and wastewater

- Boiler feed water

- High purity water

- Food processing wash water

- Chemical plant cooling water

- Many other aqueous systems that require reliable pH monitoring

F12D Toxic Gas Detector

- 60 different interchangeable smart sensors

- AutoTest sensor verification*

- Heated sensor option

- Remote sensor capability

- Internal data logger

- Wastewater treatment plants

- Chemical plants

- Pharmaceutical and medical

- Semiconductor fabrication

- Food processing

- Mineral processing

- Gas processing

D12 Toxic and Combustible Gas Detector

- Multiple configurations including: Loop Powered Transmitter, Loop Powered with HART™, Transmitter with Integral Relays and Transmitter with Modbus™

- Explosion Proof Enclosure

- Internal Data Logger

- Chemical Processing

- Pulp & Paper

- R&D Labs

- Semiconductor Plants

- Refineries

- Pharmaceuticals

- Food Processing

- Aluminum Refining

- Breweries

- Metals Processing

- Water Treatment

- Wastewater Treatment

- Electric Utilities

- Agricultural Chemicals

- Plastics Manufacturing

D12Ex-IR Infrared Gas Transmitter

- Methane or hydrocarbon gas detection

- Explosion proof enclosure

- Two digital communication options, Modbus™ and HART™

- Available with an infrared sensor designed for CO2 measurements

- Chemical Processing

- Pulp & Paper

- R&D Labs

- Semiconductor Plants

- Refineries

- Pharmaceuticals

- Food Processing

- Aluminum Refining

- Breweries

- Metals Processing

- Water Treatment

- Wastewater Treatment

- Electric Utilities

- Agricultural Chemicals

- Plastics Manufacturing

GasSens Midi Controller

- 1 to 64 addressable sensors

- Network up to 16 controllers

- Public buildings

- Breweries

- Boiler plant rooms

- Water treatment works

- H&V control

- Manufacturing

- Process plants

- Horticulture

- Hotels

- Offices

Overview

The ATi water quality monitoring and toxic gas detection system offers an automated solution for continuous measurement and recording of water quality and toxic gas indicators throughout the Food & Beverage production process. This solution plays a critical role in ensuring that manufacturing facilities adhere to strict safety, sanitation, and regulatory standards, thereby safeguarding employee health and enhancing product quality.

With its advanced monitoring system, ATi supports businesses not only in optimizing production processes but also in effective risk management, providing absolute assurance for Food & Beverage facilities. The system meets stringent environmental and public health safety requirements, reinforcing ATi’s commitment to quality control and sustainability.

Advantages of the ATi System:

- Comprehensive Water and Air Quality Control: ATi’s monitoring system provides precise and reliable control over water quality and toxic gas detection, helping production facilities maintain clean water and air sources that meet the highest hygiene and safety standards. ATi’s equipment monitors incoming water quality, disinfection processes, and cooling stages, ensuring a stable and safe production environment while maintaining consistent product quality.

- Flexible and Diverse Application Options: ATi’s solution integrates easily across various sectors within the Food & Beverage industry, including beverage production, meat processing, chocolate manufacturing, breweries, wineries, fermentation facilities, and service venues like bars and restaurants. ATi’s sensor technology supports monitoring of essential processes such as disinfection, cooling, and sanitation, helping optimize efficiency, minimize risk, and uphold safety standards.

- Ensuring Safety and Regulatory Compliance: The ATi system strictly adheres to safety and regulatory standards, protecting employees from toxic gas exposure and ensuring a safe working environment. With ATi’s comprehensive monitoring solution, businesses in the Food & Beverage industry can confidently meet legal requirements and support sustainable production growth.

Applications

- Beverage Production: ATi’s water quality and disinfection monitoring system ensures water meets standards, preserving product purity and flavor quality.

- Meat Processing: ATi’s toxic gas and water quality monitoring equipment upholds rigorous sanitation conditions, ensuring employee safety and product quality.

- Chocolate, Beer, and Wine Production: ATi technology manages temperature, humidity, and gas levels throughout production, ensuring consistent quality and a safe working environment.

- Bars and Restaurants: The CO2 detection system helps control beer storage environments, ensuring safety for both staff and patrons.

-

Fermentation Facilities: ATi aids in managing CO2 and O2 concentrations, optimizing fermentation processes, maintaining high product quality, and ensuring operator safety.