1.The importance of dissolved oxygen (DO) and the operational electricity cost of water aeration fans or air blowers in intensive shrimp farming

In shrimp farming, maintaining dissolved oxygen levels above 4 mg/l (ideally 6-8 mg/l) in the ponds is crucial for success. Providing adequate oxygen throughout the farming cycle helps shrimp grow well, stay healthy, and thus reduce excess feed in the ponds. With low excess feed in the pond, water quality is improved, reducing diseases caused by bacteria, while also reducing the accumulation of toxic substances such as H2S, NO2, in the water. Dissolved oxygen levels have the most significant impact on shrimp survival rates during the first 10 days, and immediately after molting, shrimp require twice the normal oxygen levels.

Currently, in shrimp ponds, electricity sources include single-phase and three-phase electricity, as well as single-phase household electricity. Electricity costs in whiteleg shrimp (Litopenaeus vannamei) farming with plastic-lined ponds account for 7.05%, in earthen ponds 6.28%, and in black tiger shrimp (Penaeus monodon) farming, it’s 7% of the total shrimp farming cost. According to information from the Vietnamese Fisheries Magazine, the electricity usage in shrimp farming is as follows:

- In whiteleg shrimp farming with plastic-lined ponds, the electricity usage is 150,282 kWh/ha/crop, with 3,234 kWh/ton of shrimp, and the electricity cost is 5,085 VND/kg of shrimp.

- In whiteleg shrimp farming with earthen ponds, the electricity usage is 26,775 kWh/ha/crop, with 2,913 kWh/ton of shrimp, and the electricity cost is 4,513 VND/kg of shrimp.

- In black tiger shrimp farming, the electricity usage is 21,540 kWh/ha/crop, with 4,172 kWh/ton of shrimp.

Oxygen supply systems consume about 80% of the total electricity used in shrimp ponds. With significant electricity consumption costs, shrimp farmers face difficulties in expanding their pond scale. To minimize electricity consumption by oxygen supply equipment and thereby increase investment efficiency in shrimp farming, Reecotech Co., Ltd. has developed a solution for continuous dissolved oxygen (DO) monitoring – automatic control of water aeration fans in shrimp ponds. According to recorded data, the application of this scientific and technical solution helps reduce electricity consumption for oxygen supply equipment by up to 30%.

2. Continuous dissolved oxygen (DO) monitoring solution – automatic control of water aeration fans or oxygenation equipment

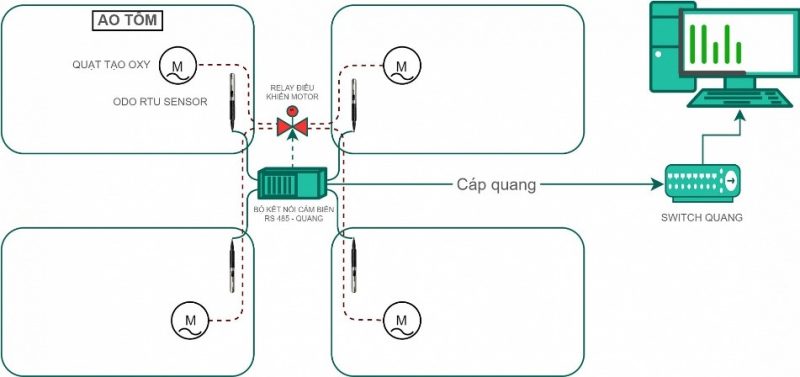

Reecotech is a leading experienced provider in Vietnam of automatic monitoring and early warning solutions for water quality. With the requirement for continuous monitoring of DO levels and automatic control of water aeration fans or air blowers in shrimp ponds to save electricity costs and optimize investment efficiency, Reecotech proposes the following solution as briefly described in the connection diagram below:

Accordingly, DO sensors using durable optical sensor technology with fast response times will be used to continuously monitor DO levels at a location in the pond where DO levels are expected to be the lowest. These DO sensors will be connected to a sensor connection unit placed at the control station on the shore. The sensor connection unit collects data from the DO sensors and transmits it to the central computer via optical cable (costing about 7,000 VND/m) and an optical signal converter. In addition, water aeration fans or oxygenation equipment in shrimp ponds will be connected to control relays. These relays automatically control the operation of motorized equipment, specifically turning on the machines when DO levels drop below 4 mg/l and turning off the machines when DO levels exceed 4 mg/l (or a DO level set according to customer requirements) to save electricity. DO levels in the ponds are continuously updated in real-time on the computer screen (or on a smartphone app, optional), allowing shrimp farmers to continuously monitor their ponds easily, and take timely actions when DO levels drop below the required level.